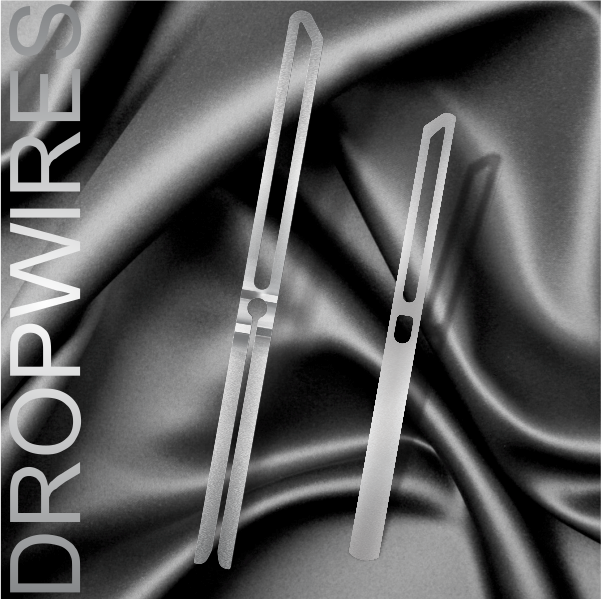

Dropwires

Specification

- Length; 80mm to 268 mm

- width 7 m to 15 mm

- Thickness 0.2 mm to 1.00 mm

- Mechanical warp stop Motion

- Electrical warp stop Motion

Execution

- High Carbon Steel Strips

- Stainless Stell (Inox)

- Electro Nickle Plating

- Zinc Plating

- Blue Finish

- Golden Yellow Finish

Suitable for all types of Automatic Drawing-In Machines

We also make customized dimension as per request. A sample or draft is required for the same| MECHANICAL MO=MECHANICAL OPEN MC=MECHANICAL CLOSE |

ELECTRICAL EO=ELECTRICAL OPEN EC=ELECTRICAL CLOSE |

|||

| Drop wire weight | Length mm | width mm | Thickness mm | weight gm |

| MC/EC | 125 | 11 | 0.2 | 1.7 |

| 0.3 | 2.5 | |||

| 0.4 | 3.3 | |||

| MO/EO | 145 | 11 | 0.2 | 1.7 |

| 0.3 | 2.5 | |||

| 0.4 | 3.3 | |||

| MC/EC | 145 | 11 | 0.2 | 1.9 |

| 0.3 | 2.9 | |||

| 0.4 | 3.8 | |||

| 0.5 | 4.8 | |||

| MO/EO | 165 | 11 | 0.2 | 1.9 |

| 0.3 | 2.9 | |||

| 0.4 | 3.8 | |||

| 0.5 | 4.8 | |||

| MC/EC | 165 | 11 | 0.2 | 2.2 |

| 0.3 | 3.3 | |||

| 0.4 | 4.4 | |||

| 0.5 | 5.5 | |||

| MO/EO | 180 | 11 | 0.2 | 2.2 |

| 0.3 | 3.0 | |||

| 0.4 | 4.4 | |||

| 0.5 | 5.5 | |||

| Weight of the drop wire gm | Tex | Material in the wrap | Silk | |

| Metric Count Nm | English Count Neb | Filament Td | ||

| 0-1 | 0 - 9 | 0 - 110 | 0 - 65 | 0 - 80 |

| 1 - 1,5 | 9 - 14 | 110- 70 | 65 - 42 | 80 - 125 |

| 1,5 - 2 | 14 - 20 | 70 - 50 | 42 - 30 | 128 - 180 |

| 2 - 2,5 | 20 - 25 | 50 - 40 | 30 - 24 | 180 - 225 |

| 2,5 - 3 | 25 - 32 | 40 - 30 | 24 - 18 | 225 - 290 |

| 3 - 4 | 32 - 58 | 30 - 17 | 18 - 10 | 290 - 520 |

| 4 - 6 | 58 - 96 | 17 - 10 | 10 - 8 | 520 - 860 |

Product Information

High quality stainless steel (INOX) for resistance to corrosion wear and breakage.

UTA’s drop wires are made from high grade stainless steel suitable for all type weaving yarns.

High quality Nickel and Zinc Plating Carbon Steel for special purpose weaving.

Carbon steel is high grade materials and plated with highly smooth finishing on the drop wires, providing smooth surfaces for yarns, while protecting the base metal characters.

Precision stamping for dimensional accuracy and consistency from lot-to-lot.

Proven methods of precision stamping assure consistency across lots and orders. These processes have been finely tuned since many years working in a collaborative effort with some of the leading international weaving accessories experts.

High capacity manufacturing for large quantity orders and quick delivery.

Multiple manufacturing and processing lines are available to assure high quantities and quick delivery of top quality drop wire products.

Excellent finishing process to assure smooth edge and flat surface for delicate yarns.

UTA employs a finishing methodology that combines technology with proven know-how gained over years of close collaboration with team of experts

Drop Wires suitable for all types of automatic drawing-in machines.

Efficient drawing-in is vital for the large weaving operations around the world. UTA's precision made drop wires are constructed to perform well on all types of automatic drawing-in machines, providing customers the reliability needed for efficient drawing-to-weaving processes.